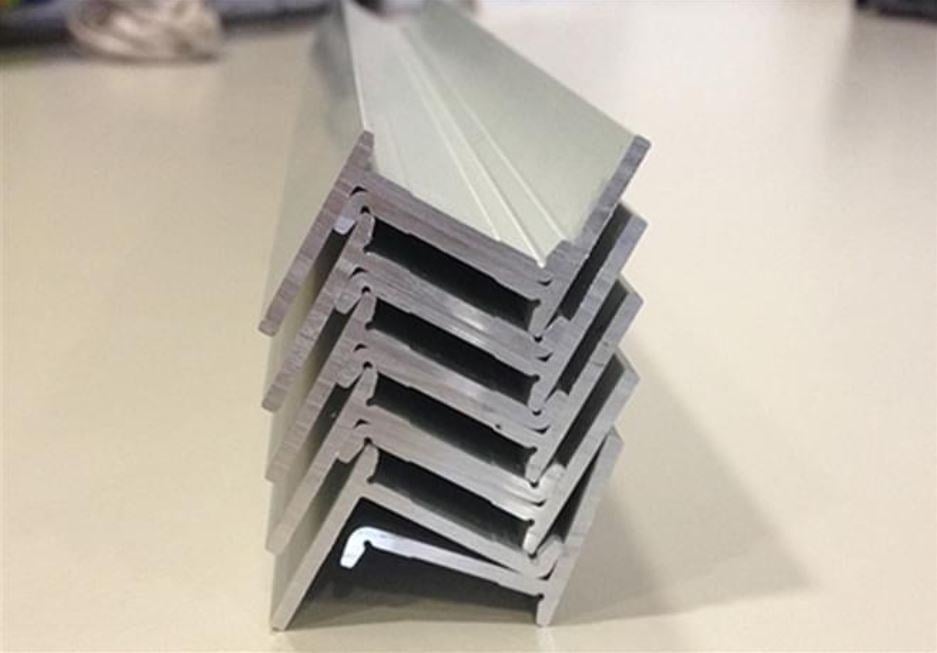

Custom aluminum corner profiles have become a key component across various industries thanks to their light weight, strength, and versatility. Ideal for both structural and aesthetic purposes, these components are used in industrial, architectural, and design applications to enhance structural stability, protect edges, and add a touch of modernity.

Learn more about:

- Profall's custom corner profile production

- Available surface treatments for your corner profiles

- Applications for custom corner profiles across different sectors

- Contact Profall for your custom aluminum corner profiles

Profall’s custom corner profile production

Thanks to aluminum’s high ductility and corrosion resistance, corner profiles ensure excellent performance even under heavy use and in outdoor environments. Profall specializes in producing corner profiles that not only meet high-quality standards but can also be fully customized to fit the most complex projects.

Our custom production service is designed to meet unique technical specifications. Our flexible production allows us to create custom aluminum corner profiles, tailored to fulfill each customer’s needs, from the simplest to the most complex requirements.

In our production process, we work closely with clients, carefully analyzing project requirements and final use conditions. Customization options include:

- Specific dimensions to perfectly fit the intended structure or design element;

- Calibrated thicknesses to ensure the necessary strength;

- Shapes and angles crafted according to client requests;

- Specialized finishes, enhancing aesthetics and performance.

With advanced machinery and technology, Profall is able to uphold high-quality standards and meet exact specifications with precision.

Available surface treatments for your corner profiles

To ensure maximum durability and strength, Profall offers a range of specific surface treatments for corner profiles.

While aluminum is naturally resistant, it can be further enhanced by treatments such as:

- Anodizing – one of the most common treatments for aluminum profiles, anodizing creates a protective layer that preserves the metal from corrosion, giving the profile an elegant, uniform appearance.

- Powder coating – ideal for clients looking to personalize the color and aesthetics of their corner profile. The coating also increases scratch and impact resistance.

- Special treatments – upon request, we can apply other finishes that meet specific needs for resistance to atmospheric or chemical agents.

These treatments not only improve the corner profile’s appearance but also extend its longevity, allowing clients to create projects that remain unchanged over time.

Applications of custom corner profiles across different sectors

Thanks to their versatility, custom aluminum corner profiles are used in many sectors, from architecture to automotive, furniture, and aerospace industries.

- Architecture – used in construction, facades, and decorative elements, custom aluminum corner profiles adapt seamlessly to contemporary architectural projects where modern aesthetics merge with the need for durability.

- Automotive – custom corner profiles can serve as lightweight, durable structural components, ideal for enhancing vehicle performance without compromising strength.

- Furniture – in interior design, custom aluminum profiles offer solutions for furniture and decor, bringing a modern and minimalist touch to spaces.

- Aerospace industry – here, aluminum plays a crucial role due to its lightness and strength. Custom profiles are used to create safe, lightweight structural components essential in a weight-critical industry.

Contact Profall for your custom aluminum corner profiles

For high-quality, custom aluminum corner profiles backed by a specialized company, contact Profall. We are available for consultations, quotes, and technical support, ready to help manufacturing companies bring unique and innovative projects to life.

Tags:

Aluminum profileNov 12, 2024 11:54:56 AM