Learn more:

- the Profall T-track range

- customization possibilities

- Profall services

- aluminum alloys used

- aluminum T-track application fields

Our aluminum T-track range

Resistance, durability and precision are the characteristics that immediately catch the eye of our t tracks: they are, in fact, safe and certified aluminum profiles according to the European regulations in force.

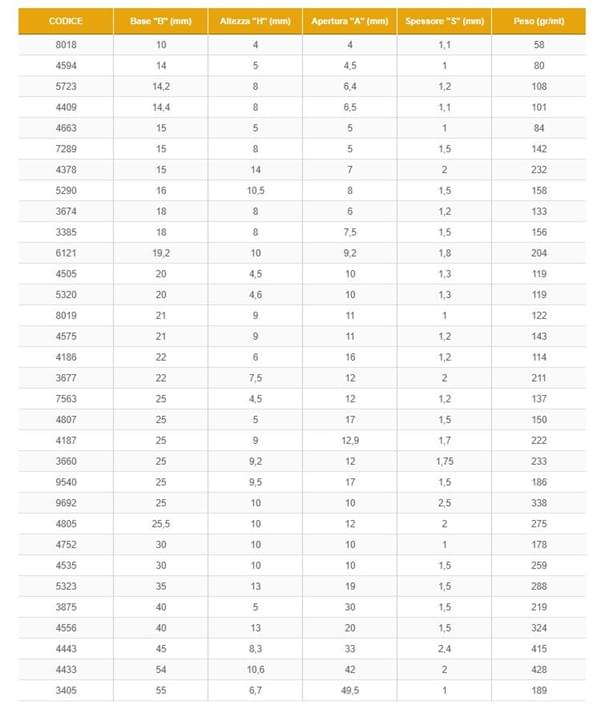

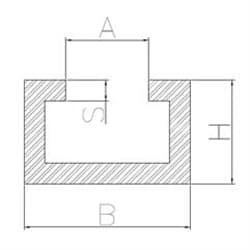

In fact, the Profall catalog includes 32 types of standard aluminum T-tracks with:

- height H from0.157 in to 0.51 in

- base B between 0.39 in to 2.16 in

- variable thickness S from 0.04 in to 0.98 in

- opening A between 0.157 in to 1.95 in

View all the available T-tracks in the following table:

C profiles are used in sectors such as mechanical, electronic, construction, domestic and automotive. Are you looking for high quality aluminum C profiles? The Aluminum Profile team is highly specialized in the production of any type of sections and extrusions, constantly investing in research and development to guarantee an ever better product.

Learn more about our product specifications

Are you looking for custom and/or small aluminum T-tracks? No problem.

If you can’t find the T-track you need in the table above, do not worry: at Profall we manufacture any sized aluminum profile, even small and minute, with +/- 0.006 inch standard dimensional tolerances.

If you can’t find the T-track you need in the table above, do not worry: at Profall we manufacture any sized aluminum profile, even small and minute, with +/- 0.006 inch standard dimensional tolerances.

Our experience and know-how gained over the years allows us to manufacture t slots with any feature the customer requires. In fact, one of the company's main strengths is the customer-oriented approach, always aimed at listening to and solving specific customer needs for all aluminum profiles.

Fully customized profiles

The partnership with RC Ramera and the use of technologically advanced machinery allow us to offer numerous services to customize and create completely customized aluminum T-tracks through:

- various cutting and shearing processes

- surface treatments to remove any impurity and meet any color, hardness and sheen request

- packaging, with the possibility of applying logos, bar codes, and other specific markings

Which t tracks do you need?

Small lots and worldwide shipping: Profile services

In addition to the possibility of requesting and obtaining totally customized t tracks, Profall offers you a series of competitive advantages, which include:

- the possibility of ordering small batches of t tracks – starting as low as 441 lbs.

- fast delivery with prototyping in about 2 weeks from order approval date

- worldwide shipping at a reasonable cost

- after-sales technical support

Aluminum alloys used for our aluminum T-tracks

We manufacture various types of T-tracks made of various types of aluminum alloys such as 1050, 1070, 3103 and 6060, the so-called "soft" alloys, according to end use.

For example, 1000 series alloys have a degree of aluminum content purity equal to a minimum of 99.5% which gives them high electrical and thermal conductivity; moreover, they are characterized by excellent corrosion resistance.

3000 series alloys, whose main element is Manganese, have the advantage of having a high resistance to corrosion and are used in braze welding technologies. This category includes aluminum T-tracks used in the automotive industry.

6000 series alloys are composed of alloying agents such as Silicon and Magnesium and are characterized by good machining and welding capabilities.

Aluminum T-track uses

In general, aluminum t tracks are widely used in the building sector, especially for the construction of plasterboard structures or to install insulation panels, a trend in constant growth, given the increasing need to build eco-sustainable buildings with high energy efficiency.

More specifically, we can say that retail t tracks are used in various sectors according to their alloys:

- Aluminum t tracks made with 1000 series alloys are typically used in the electric and electromechanics sectors

- Open t tracks made with 3000 series alloys are typically used in the automotive sector and in heat exchangers

- 6000 series alloys are used to make t tracks to be inserted inside welded structures in general and mechanically machined components - they can be used in most of the extruded designs for all industrial uses

Do you need aluminum T-tracks to finish your project?

Tags:

Aluminum profileSep 6, 2019 12:00:00 AM