In this article, we will delve into:

- Aluminum extrusions to build boats

- Which ships use these extrusions

- The best aluminum alloys

- The advantages of anodized aluminum

The aluminum extrusions you can use to build boats

In Profall’s catalog, you will find two main types of aluminum extrusions used in the naval industry to build boats and other ships: standard profiles and special profiles.

Other than these, you can ask us for customized profiles manufactured according to your application needs. Let’s delve more into these products:

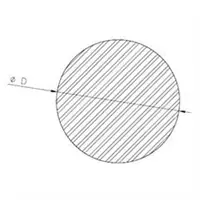

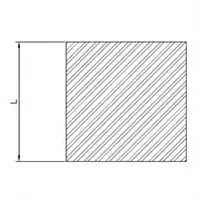

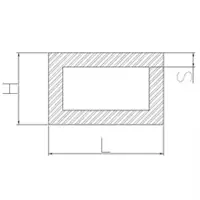

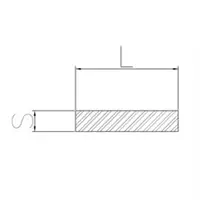

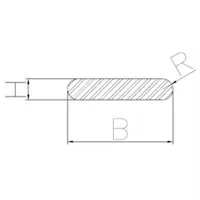

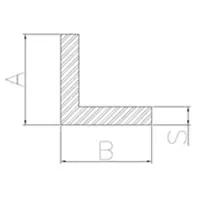

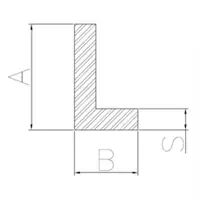

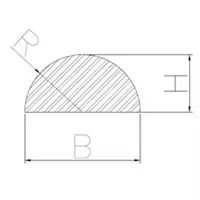

Standard profiles

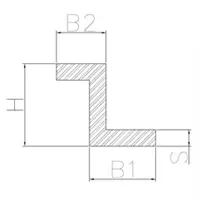

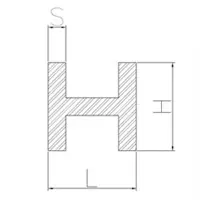

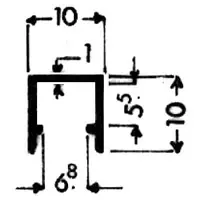

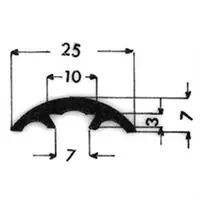

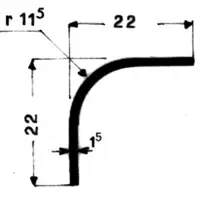

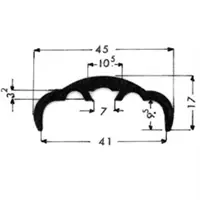

Standard aluminum profiles are extrusions made in simple shapes, sizes, and dimensional tolerances. They are manufactured with the 1050, 1070, 3103, and 6060 aluminum alloys and are used in the naval industry as essential boat components.

Here follow all the products in our catalog:

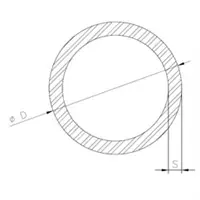

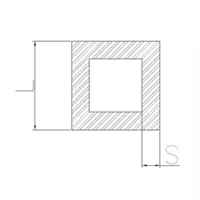

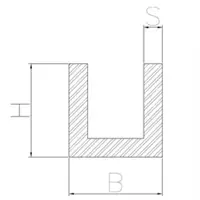

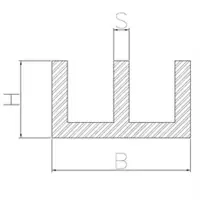

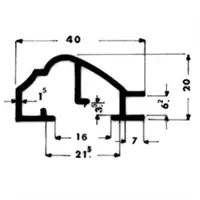

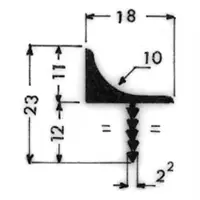

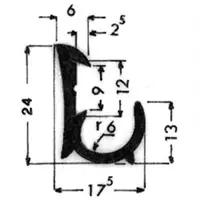

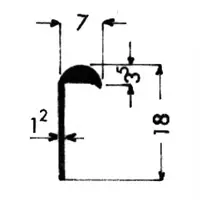

Special profiles

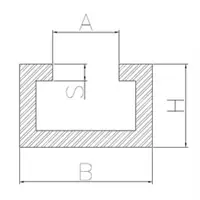

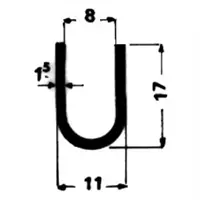

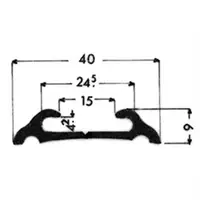

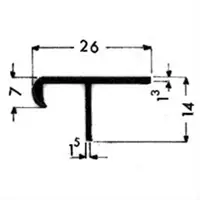

On the other hand, special extrusions are profiles with specific shapes, sizes, and dimensional tolerances. They are manufactured with the 6060 aluminum alloy, which offers unique qualities, and are used in the naval industry as essential boat components.

Here follow all the products in our catalog:

Customized profiles

If the profiles you’ve seen thus far don’t exactly meet your needs, you can ask us for the manufacturing of the boat aluminum extrusions you are looking for. Thanks to our customization service, we can turn your technical drawing with mechanical features into the finished product you wish for.

Customization doesn’t only concern the shape, the size, and the materials used to create your profile, but also the possibility to perform several treatments and surface finishes, such as:

- Cutting to size

- Drilling and micro drilling

- Shearing

- Milling

- CNC machining

- Bending and calendering

- Anodizing

- RAL painting

Are you looking for aluminum boat extrusions? Choose Profall’s products!

Which boats resort to aluminum extrusions?

The types of boats that resort to extruded aluminum are countless: we’re talking about not only private and personal ships but also commercial and military vessels. According to its dimensions, in fact, aluminum is ideal for small and big boats, thanks to its distinguished versatility.

For example, you will find components made with extruded aluminum in the following boats:

- sailboats

- yachts

- motorboats

- fishing boats

- ferries

- cruise ships

- military ships

Aluminum lightness is the main feature that makes it the perfect extrusion for boats. Thanks to its reduced weight, in fact, it allows ships to improve their speed and reduce energy consumption.

The best aluminum alloys for boats

In the boat construction process, not every extruded aluminum type can be ideal. The main two alloys are the 5083 and 5086, which are specific for naval use:

- Aluminum 5083 offers resistance to corrosion, shock absorbing capacity, and lightness, in fact it’s used mainly in sailboats and motorboats that need to be fast and maneuverable

- Aluminum 5086, instead, offers higher resistance, both to corrosion, shocks, and thermal stress, which makes it ideal to build boats that need to face aggressive marine environments and high-power motorboats

Other extruded aluminum alloys employed to build boats are:

- the 6061 and 6082, which are high-resistance alloys

- the A356 and the A357, which come from die-cast aluminum

- the 6061-T6 and the 7075-T6, which are heat-treatable aluminum alloys

The advantages of anodized aluminum extrusions for boats

Using boat aluminum extrusions brings several advantages, among which figure lightness and resistance to different environmental factors. Nevertheless, if you consider asking to perform anodizing on your product you can gain additional benefits.

Anodized boat aluminum extrusions, in fact, offer higher technical and mechanical properties thanks to this specific treatment. For example, they:

- obtain a unique esthetical aspect, since anodizing gives a specific coloration to the piece and makes it suitable for different contexts

- become even more resistant to corrosion and shocks

- can be treated easily and are also compatible with welding

If aluminum is a material that proves to be beneficial compared to other metals on the market, anodizing multiplies its qualities, thus making it perfect to build boats.

For your boats, choose Profall’s aluminum extrusions

Ask for further information

Create without limits: get a quote for your custom aluminum profile.

Tags:

Aluminum profileSep 6, 2023 12:00:00 AM