If you are looking for high precision profiles, you must choose a company with a lot of experience in aluminum extrusion. Profall is able to produce the most suitable profiles for your specific needs, even with special designs, of small and very small dimensions.

Are you looking for a company able to produce high quality extruded aluminum products?

Aluminum extrusion was conceived in 1770, but the technological process, as we know it today, was only consolidated in the second half of the last century, for the creation of industrial materials for each product sector.

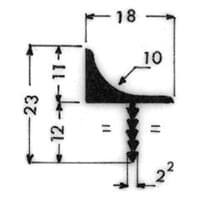

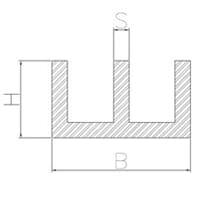

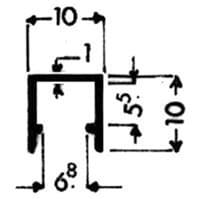

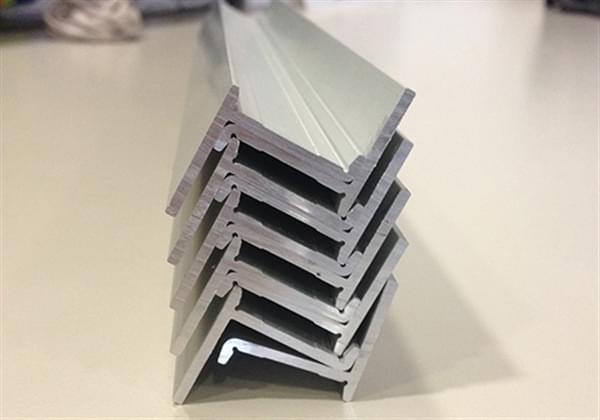

This aluminum processing is a highly complex technical process where attention to detail really makes the difference. The extrusion of aluminum is declined in different profiles according to industrial needs, for jobs that often require very high precision. Profall has proved to be a leading company able to extrude aluminum for any branch of the technological market, creating aluminum profiles of high technical complexity.

Aluminum extrusion: how it works

Starting aluminum extrusion means compressing a cylindrical aluminum block with the aid of a horizontal press, so that it forcibly passes through the holes in the matrix and returns a constant-section aluminum profile.

Aluminum extrusion: fields of use

Thanks to the excellent mechanical properties of this material, aluminum extrusion is required in almost all industrial sectors, especially in the furniture, automotive, and construction sectors. Both standard profiles are required, such as bars and tubing, and profiles with special and customized sections.

- Transport: In this sector, aluminum extrusion is mainly used for the preparation of various types of transportation, including buses, trains, and boats. In humid environments or in direct contact with water it is possible to use anodized aluminum profiles to avoid oxidation.

- Furnishing: the furnishing sector and, more generally, the design sector, use aluminum extrusion to create useful profiles for furniture, curtains, fixtures, doors and windows – we are aluminum window extrusions suppliers –, etc.

- Lighting: in this sector aluminum profiles are used to make LEDs, totems, lamps and also perform the function of dissipating the lighting element.

- Electronics: in the electronics field, aluminum extrusion is used for the production of elements for photovoltaic panels, inverters, and heat sinks.

- Electromechanics: in the electromechanical sector, aluminum profiles are used for their electrical conductivity. In fact, thanks to the extrusion of aluminum in high purity content alloys, it is possible to make extrusions for electrical transformers.

- Automotive: in the automotive sector, aluminum extrusion is useful for creating components for radiators, pipes for fluid distribution, and for other elements of air conditioning systems.

Profall advantages

Profall is a company based in Bergamo that produces high quality extrusions in aluminum, also in small and very small sizes, with a high level of complexity. The Profall team of professionals is able to advise you and build aluminum profiles based on your specific needs.

- Profall team's extensive experience guarantees unique expertise in the sector.

- Profall constantly invests in the research and development of new technological solutions.

- Profall creates aluminum extrusions in many different alloys, depending on the required use.

- The company from Bergamo specializes in the production of high-tech extrusions, even small and very small.

- Profall relies on cutting edge and updated machinery.

- Supplies can be produced in small lots.

- Profall guarantees its full support for all your needs and fast deliveries.

Which aluminum profiles do your need?

Tags:

Aluminum profileMay 9, 2019 12:00:00 AM