In fact, aluminum is extruded thanks to the use of high precision machinery, from which constant section pieces are obtained, such as tubes or profiles of different shapes, weights, and dimensions.

There are two main types of aluminum extrusion profiles produced by Profall:

- standard aluminum extrusion profiles for the transport, automotive, electronics, electromechanical, and lighting sectors;

- special aluminum extrusion profiles for furniture, automotive, technical furniture, etc.

Both types of extrusion profiles can be customized according to the needs and the sector of use.

Do you need aluminum extrusion profiles for your project? Profall can help you

The strong point of Profilati Alluminio is the design and production of customizable aluminum extrusion profiles, both standard and special and also anodized, with small and very small dimensional tolerances, which other companies are unlikely to guarantee.

The new partnership with RCRAMERA also allows Profall to expand the range of its solutions, including:

- aluminum cutting and shearing;

- extrusion profile surface finishing;

- packaging, with the possibility of applying logos, bar codes, and specific identifications.

After your order of aluminum extrusion profiles

Profall not only deals with the design and production of various types of aluminum extrusion profiles but also pays close attention to customer service. In fact, in addition to responding to requests quickly and proceeding rapidly with the feasibility analysis, prototyping, and pre-series production, the company also guarantees an after-sales service.

Aluminum extrusion profiles are designed to be high quality and functional, but if there is a technical problem, just contact Profall: the solution will be found quickly.

Custom aluminum extrusion profiles: the example of picture frames

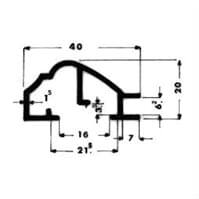

Frames are a type of special aluminum extrusion profile that is used to make frames for paintings, windows, mirrors, windows and more. They are generally made up of a pair of profiles: one is the base and wall fastening element, and the other is the snap closure element to secure the glass or other materials.

Thanks to its high-tech machinery and the team of technicians and engineers, during 2019 Profall collaborated with MSC Crociere for the construction of the frames to hang paintings in the ship's cabins. The task involved:

- the design study, all made to measure according to the indications of the company;

- the realization of the aluminum extrusion profiles and their assembly, with the indicated painting inside each;

- the preparation of the packaging, with an indication of the characteristics of each frame and the destination cabin;

- frame shipment.

Do you need aluminum extrusion profiles?

Tags:

Aluminum profileMar 10, 2020 12:00:00 AM