In this article we will delve into:

Today, the use of aluminum is affecting every industrial sector. Since it’s a resistant and easy-to-work metal, it allows the creation of a wide range of finished products and extrusions, even for industrial automation.

The extrusions that are most demanded in this field, for example, are:

- bars for rollers

- sound-absorbing profiles

- profiles for foot traffic

- profiles for conveyors

- cable drag channel extrusions

- profiles for frames

Our range of aluminum extrusions for automation

Standard or special, we provide different types of aluminum extrusions for automation use. Here’s Profall’s range of profiles – each of them is widely customizable according to your specific needs:

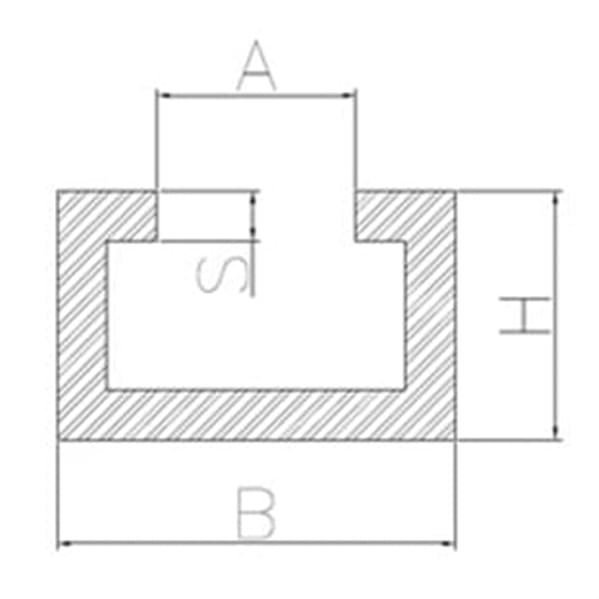

T-tracks

Aluminum T-tracks are standard extrusions designed to be used as tracks mainly in the mechanical, electronics, building, and automotive industries. With a dimensional tolerance of +/- 0.15mm, they can be manufactured even in very reduced sizes.

Their production resorts to the following aluminum alloys: 1050, 1070, 3103, and 6060.

Thanks to their lightness, easy installation, resistance to corrosion and external agents, and incredible versatility, these aluminum extrusions are perfect to be used in the automation field.

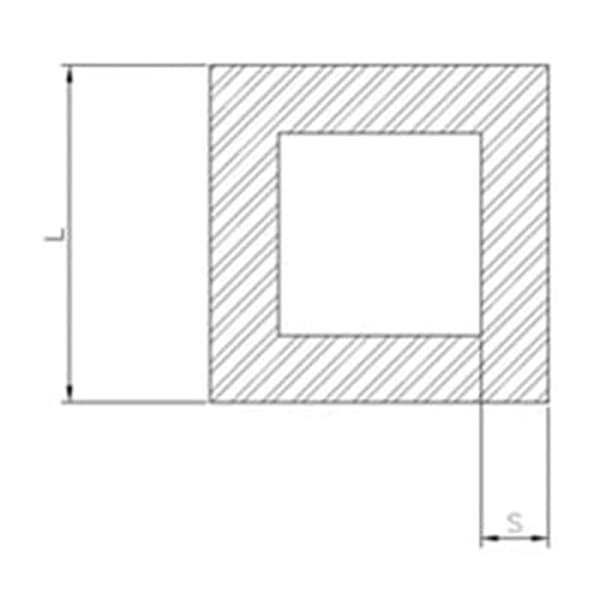

Square, round and rectangular tube

In Profall’s catalog, you can also find aluminum tubing that is suitable for automation, such as:

These profiles are used in the mechanical and electromechanical, automotive, building, and furnishing industries. With a dimensional tolerance of +/- 0.15mm, they can be designed even in very reduced sizes.

Their production resorts to the following aluminum alloys: 1050, 1070, 3103, and 6060.

These extrusions are ideal for automation because they are capable of offering durability and resistance, high elasticity, a good vibration-damping capacity, and excellent dimensional stability.

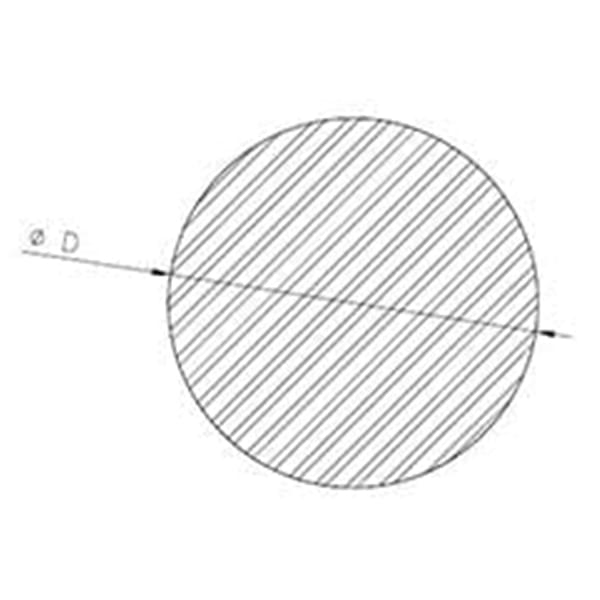

Square, round, flat bars, and flat bars with rounded edges

Among standard profiles ideal for automation, Profall’s catalog also includes:

These bars are mainly employed in the mechanical and electromechanical, building, and furnishing industries. They present a dimensional tolerance of +/- 0.15mm but they can be designed even in very reduced sizes.

Their production resorts to the following aluminum alloys: 1050, 1070, 3103, and 6060.

Among the qualities they boast, there’s their versatility, resistance, lightness, and easy installation.

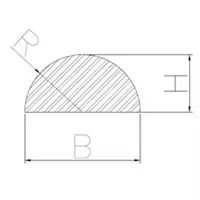

Semicircular elements

Semicircular elements, instead, are standard aluminum extrusions for automation whose shape is a round bar cut in half. Thus, they present a flat side, which can be laid on every surface, and a rounded side.

Their production resorts to the following aluminum alloys: 1050, 1070, 3103, and 6060.

Apart from automation, these extrusions are mainly used in the building, mechanical and electromechanical, and furnishing industries.

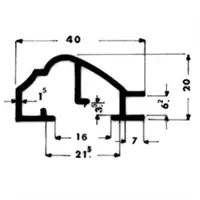

U channels, special U profiles, and double ducts

Other standard aluminum extrusions for automation are:

Channels and ducts are perfect as track profiles, thus they mainly find applications in the electronic and electromechanical, automotive, furnishing, building, and domestic fields.

Their production resorts to the following aluminum alloys: 1050, 1070, 3103, and 6060.

Other than these, there’s also a specific type of channel, which is called a special U profile: this extrusion presents a non-standard shape and dimension and can be adapted to your use requirements.

Picture frames

Finally, even picture frames find widespread use as extrusions for automation. These special extrusions, in fact, present a 45° cut and are designed to house fastening and corner assembly brackets.

Other than automation, picture frames are used in the building and furnishing industries as components for windows, doors, mirrors, and much more.

They are made with the 6060 aluminum alloy, which guarantees protection, resistance, versatility, flexibility, and robustness.

Choose Profall’s aluminum extrusions:

Why are aluminum extrusions highly demanded in automation?

Grazie a questi benefici, i profili in alluminio contribuiscono a diventare parte fondamentale di sistemi modulari studiati per automatizzare processi aziendali e industriali.

Aluminum extrusions are widely used in industrial automation mainly because of the following reasons:

- they can be easily assembled and disassembled so that possible modifications can be practically made

- they don’t require specific finishings since, for example, aluminum doesn’t need rustproof treatments – which is common for iron products

- they are long-lasting because they resist the corrosion resulting from external agents, but also thermal stress and shocks

- aluminum can be recycled so, once its life cycle is over, extrusions for automation can be recycled and reused in other situations.

Thanks to these benefits, aluminum extrusions contribute to becoming a fundamental part of modular systems designed to automate industrial and company processes.

Profall: customization, technical support, worldwide shipping

One of the biggest advantages of Profall is the possibility to demand completely customized aluminum extrusions for automation: in fact, our strong suit is the design and production of 100% tailor-made profiles even with high technical complexity, very reduced dimensional tolerances – that are hard to find elsewhere –, and specific treatments.

The customization of your aluminum extrusion for automation starts with a drawing you can send us – in which all the technical and mechanical features are included – and that our team of experts will analyze to test its feasibility. Once this step is completed, we will proceed with the prototyping of the desired product and its pre-series production.

But that’s not all, because with Profall you:

- can order small batches of aluminum extrusions for automation – generally starting from 300 kg for the bar format and 500 kg for the reel one.

- are guaranteed that the delivery is express, with about 2 weeks of prototyping starting from the date of the order approval

- receive your extrusions everywhere you are – we ship worldwide at reasonable costs

- receive after-sale technical support

Choose Profall’s aluminum extrusions:

Tags:

Aluminum profileSep 6, 2021 12:00:00 AM