Anodization is an electrochemical treatment that increases the oxide layer on the surface of aluminum, improving its aesthetic and functional characteristics. This process not only makes aluminum more resistant to corrosion and wear but also allows for a wide range of colorful finishes that can meet diverse aesthetic and design requirements.

Let's delve into its advantages in flat profiles in this article, where we'll explore:

- Anodized flat aluminum profiles by Profall

- Advantages of anodized flat aluminum profiles

- Industrial applications of anodized flat profiles

- Why choose Profall as your supplier?

Anodized flat aluminum profiles by Profall

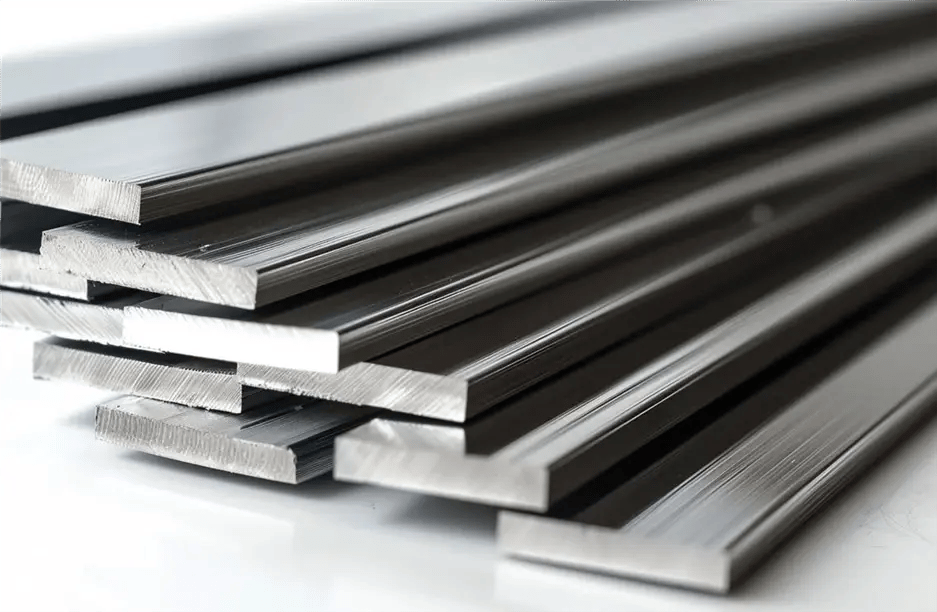

Anodized flat aluminum profiles offer a unique combination of lightness, strength, and versatility. Profall manufactures these profiles using high-quality alloys such as 1050, 1070, 3103, and 6060, ensuring precise dimensional tolerances and excellent durability.

Thanks to anodization, profiles can be customized to fit specific industrial applications, with finishes ranging from natural silver to vibrant and decorative colors.

Advantages of anodized flat aluminum profiles

- Corrosion and wear resistance - The oxide layer formed on the surface of aluminum acts as a protective barrier against atmospheric and chemical agents, making the profiles suitable for use in harsh and aggressive environments.

- Enhancement of aesthetic properties and color durability - The ability to achieve a wide range of colors through the anodization process allows these profiles to be used in applications where visual appearance is crucial, such as in architecture and interior design. Additionally, the colors obtained are stable over time and resistant to the effects of light exposure and weathering.

- Increased surface hardness and ease of maintenance - The anodized layer increases the surface hardness of aluminum, improving its resistance to scratches and abrasions. This makes anodized flat profiles particularly suitable for applications requiring a robust and durable surface. Maintenance of these profiles is straightforward, requiring only periodic cleaning to maintain their original appearance.

Industrial applications of anodized flat profiles

- Aerospace - In the aerospace industry, anodized flat aluminum profiles are used for constructing lightweight and durable structures such as frames and structural components. The corrosion resistance and high durability of anodization are essential to ensuring the safety and longevity of aerospace components.

- Automotive - In the automotive sector, these profiles are used in the production of aesthetic and functional parts such as interior and exterior finishes, panels, and supports. The ability to customize color and finish allows designers to create vehicles with a unique and appealing appearance.

- Construction - In construction, anodized flat aluminum profiles are used to create decorative and functional elements such as facades, window frames, and load-bearing structures. Their resistance to atmospheric agents and ease of maintenance make them ideal for both exterior and interior applications.

Why choose Profall as your supplier?

Profall is distinguished by the reliability and quality of its products. This value is reflected in its commitment to meeting customer needs promptly, ensuring on-time deliveries and products that are hard to find elsewhere.

- Specialization and technical expertise are key pillars. With 90% of production dedicated to special profiles, the company accurately meets customer needs through the expertise of its staff, enabling the development of innovative and complex products that address and surpass complex technical challenges.

- Innovation is continuous, with the adoption of advanced technologies to develop effective technical solutions.

- Sustainability is a fundamental pillar. Profall promotes the use of eco-friendly aluminum, reducing ecological footprint and offering products that combine functional excellence and environmental responsibility.

Thanks to these values, Profall positions itself as a reliable and innovative partner capable of offering tailored solutions that enable customers to excel in their respective fields.

If you would like to learn more about anodized flat aluminum profiles and the customized solutions offered by Profall, contact us today. Our team of experts is ready to help you find the perfect solution for your industrial needs.

Tags:

Aluminum profileJul 12, 2024 12:00:00 AM