A varied production of aluminum profiles allows you to easily find the solution to your needs, regardless of your business sector. Are you looking for extruded profiles for lighting fixtures? We make profiles for LED. Do you work with electronics? We produce profiles for heat rejectors for computers and peripherals as well. Do you need extruded products for vehicle air conditioning systems? We can supply those as well.

And so on and so forth, for a series of sectors to which we are aluminum extrusion manufacturers

- transportation

- furniture and technical fixtures

- Lighting fixtures

- electronics

- electro-mechanic

Aluminum extrusion manufacturer: all our profiles

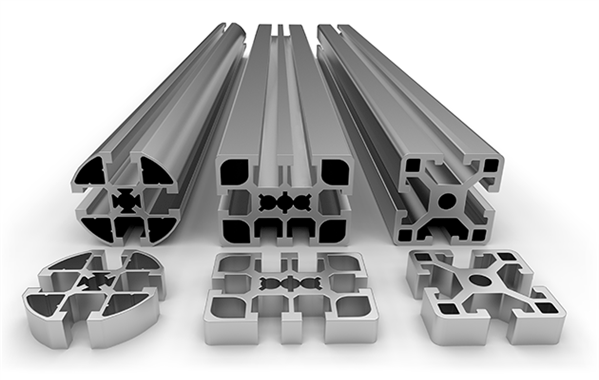

As aluminum extrusion manufacturers, our catalog includes various types of profiles we can classify into two main types, for simplification purposes:

- Standard extrusions: Angular extrusions with equal or unequal sides, flat bars (including those with rounded edges), square and round bars, tubular extrusions (round, square, or rectangular), half-round extrusions, simple and double grooves, C, Z, and H-profiles;

- Special extrusions: Special-section angular extrusions, borders to attach to screws and for vehicles, aluminum handles, handrails, and frames, coupling covers with shaft, glass stopper profiles for doors and windows, aluminum chisels, drips, and splash shields.

Looking for a full range of aluminum extrusions?

Aluminum extrusion manufacturers: request your custom-made profiles

In addition to them, our apple in the eye is a complete response to your needs: the possibility to customize the profiles in our catalog or to create new ones from scratch, based on a technical drawing.

We can produce custom-made aluminum extrusions at small or very small sizes, something difficult to find in the market, thanks to our team of qualified engineers and to our technology, which allows us to:

- Cut aluminum with different cutting machines to achieve very small sizes;

- Shear aluminum using vanguard software to respond to your needs;

- Work with aluminum surface treatment, with advanced brushing techniques to remove any impurities and guarantee any color, hardness, and sheen requirements.

Finally, you may request aluminum packaging with the possibility of applying your logo, bar code, or specific identification - something we have already done for MSC Crociere, for whom we have produced extrusions to furnish their ship cabins.

Alloys for aluminum extrusion

Producing aluminum extrusions requires, most of the time, the use of the so-called “soft alloys”, i.e. those belonging to these series:

- 1000 - Pureness degree equal to 99.5% of aluminum;

- 3000 - Consisting mainly of manganese, with high resistance to corrosion;

- 6000 - Composed of silicon and magnesium, characterized by good workability and weldability.

In particular, as aluminum extrusion manufacturers, today we use mostly alloys 1050 - 1070 - 3003 - 3103 - 3004 - 6060 - 6063 - 6005.

Each of them differs from the others in terms of composition, malleability, electric conductibility, resistance, and other factors that make them more or less suitable for the manufacturing of a certain profile.

For instance, angular pieces used in electronics, furniture, or building are produced mostly with alloys 1050, 1070, 3103, and 6060; aluminum frames for interior design, on the other hand, are mostly produced with alloy 6060.

Are you looking for aluminum extrusion manufacturers?

Tags:

Aluminum profileJul 8, 2020 12:00:00 AM