Used in a wide range of sectors, including construction, furniture, and air conditioning, Profall aluminum tubes offer several major advantages, such as:

- decreased weight compared to steel tubes

- the possibility of being anodized for corrosion resistance

- strength and durability

- certification of compliance with the international regulations

Our tubes

Due to their usage flexibility and the characteristics described above, there’s an almost unlimited range of aluminum tubes available. That’s why, in addition to the production of standard square, rectangular, and round section tubes, we’ve also been offering the possibility of ordering extrusions in fully customized shapes and sizes for years.

Let’s start with the most common aluminum tubes: the square, round and rectangular ones. Each of these can be extensively customized to the point of reaching extremely low dimensional tolerances, and this possibility has earned us a worldwide reputation as quality aluminum tube manufacturers. For example, while the tubes have standard dimensional tolerances of +/- 0.15 mm in diameter, we can also produce them with much lower tolerances, in order to fully meet the customer’s needs.

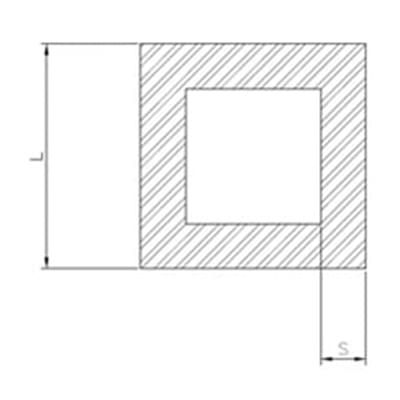

Square tubes

Used primarily in the mechanical, electromechanical, furniture, and automotive sectors, square tubes are also available for complex applications. They’re mainly produced in the alloys 1050, 1070, 3103, and 6060, depending on the relative sector and the intended use of the extruded product.

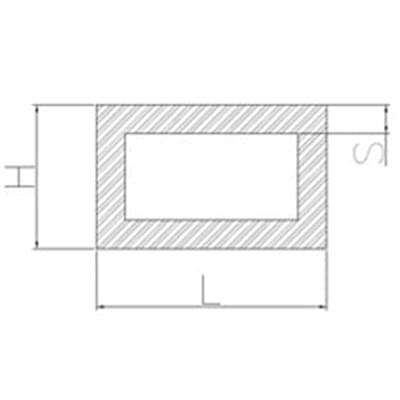

Rectangular tubes

Rectangular tubes are widely used in the construction, healthcare, and automotive sectors and, like other types of extrusions, can be produced in custom sizes.

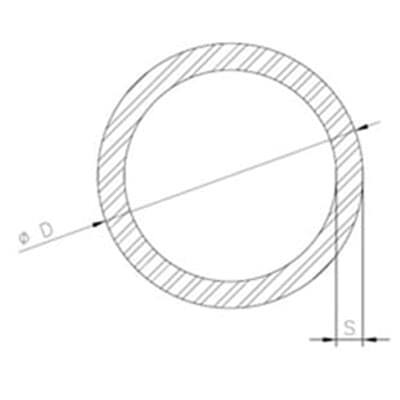

Round tubes

Last but not least, we’re also manufacturers of round aluminum tubes in soft alloys (generally from the 1050, 1070, 3103, and 6060 series). These are mainly used in the mechanical, electromechanical, construction, and furniture industries, in which very small extrusions are often required.

If you're curious to know our entire catalog, you should check out this page: Aluminum pipe manufacturers

Why you should choose Profall from among the various aluminum tube manufacturers

Given their wide range of applications, aluminum tubes often need to be highly customized in terms of both shape and size, especially in sectors like the furniture or construction industries.

But that's no problem. By contacting aluminum tube manufacturers like Profall, you can rest assured that you’ll receive custom extrusions:

- in custom shapes – designed to meet your specific needs, thanks to the use of cutting-edge software

- in custom sizes – we cut the aluminum using different types of cutting machines, which allow for extremely small tolerances to be obtained

- in custom colors – in fact, thanks to the use of specific brushing techniques, we’re able to eliminate surface impurities for paint application in any color

The type of alloy to be used for the tubes’ production is determined based on their intended use: we generally use the so-called “soft alloys” of the 1000, 3000, and 6000 series. This is a fundamental factor, because the inalterability, structural solidity, and profiles able to be obtained depend on the type of alloy.

In addition to customization, by entrusting us with the production of your aluminum tubes, we also guarantee:

- the possibility of ordering small batches – starting as low as 300 kg

- a quick feasibility analysis service

- technical support throughout the entire sales process

- the fulfillment of your order within about two weeks (we ship all over the world at reasonable prices)

- an after-sales support service

Looking for aluminum tubes?

Tags:

Aluminum profileAug 24, 2020 12:00:00 AM