In this article, you will find information about:

The H shaped aluminum extrusions in our catalog

In our extensive aluminum profile catalog, you can find H shaped extrusions. These products fall into the standard profile category because they’re manufactured with simple shapes, sizes, and dimensional tolerances.

Their design takes into account the technical and mechanical characteristics of the 1050, 1070, 3103, and 6060 alloys, while guaranteeing the utmost compliance with the existing European legislation concerning safety.

We supply our H shaped aluminum extrusions in the bar format, which can be ordered in a minimum quantity of 300 kg. For specific requirements, we can also create fully-customized profiles, both in terms of dimensions and surface finishes and treatments.

The advanced process and benefits of H shaped aluminum extrusions

Profall produces H-profiles through an advanced aluminum extrusion process, ensuring exceptional quality and precision. This process involves heating aluminum billets to a high temperature, making them malleable, and then forcing them through a die shaped like the H-profile. The resulting profiles are rapidly cooled, cut to specific lengths, and subjected to rigorous quality control checks.

This method not only allows for the creation of complex shapes with tight dimensional tolerances but also ensures high strength and durability. The benefits of this process include cost-effectiveness, flexibility in design, and the ability to meet diverse application needs across various industries.

Application fields of H shaped aluminum extrusions

Thanks to their versatility, our aluminum extrusions are widely used in different industrial and commercial applications. Specifically, they are employed in the following fields:

- construction, where they serve as mullions and transoms in building facades

- mechanics and electromechanics

- furnishing, as a support in the production of sliding elements such as tents and panels

And many other fields.

The advantages of H shaped aluminum extrusions

Our H shaped aluminum extrusions offer very distinctive properties compared to those manufactured by competitors. Their advantages are unique and irreplicable and include:

- resistance to shocks, temperatures, and external agents

- lightness

- high longevity

- precision

- easy installation

- excellent mechanical performance

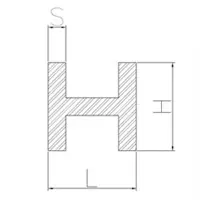

The available sizes of our H shaped aluminum extrusions

Here follows a table including all the types of H shaped aluminum extrusions we’re able to manufacture, broken down by the side length, height, thickness, and weight they’re characterized by:

| CODE | Height "H" (mm) | Side "L" (mm) | Thickness "S" (mm) | Weight (g/m) |

|---|---|---|---|---|

| 3144 | 18 | 10 | 1.35 | 155 |

| 3230 | 27 | 13 | 2 | 375 |

| 3334 | 8 | 5 | 1.25 | 60 |

| 3626 | 24 | 14 | 2 | 310 |

| 3731 | 15 | 5.5 | 1.1 | 100 |

| 3732 | 20 | 12 | 1.2 | 165 |

| 4596 | 34 | 17.2 | 1.5 | 335 |

Here at Profall, we’re able to supply you with H shaped aluminum extrusions not only in small sizes but also with very reduced dimensional tolerances. These products have complex manufacturing processes and are hard to find on the market.

Find out more about this product!

Profall: our full service and customization of H shaped aluminum extrusions

Profilati Alluminio is a company with a specialization in designing and manufacturing standard and special aluminum profiles – including H shaped extrusions. We carry out accurate and high-quality processes which guarantee that our finished products fully meet the application needs of our customers.

If this is not guaranteed through the profiles in our catalog, you can ask us to create tailor-made aluminum extrusions – even H shaped. Customization can be delivered in terms of:

- shapes and colors

- sizes and dimensional tolerances

- mechanical processing such as bending, cutting to size, drilling, shearing, milling, and CNC machining

- surface finishes such as anodizing and painting

How does our customization process unfold?

- we start from a technical drawing of the H shaped aluminum extrusion, where you will include all the mechanical and technical features you wish for

- then, we proceed to test the feasibility of the project

- if the test is successful, we carry out the profile prototyping and later its pre-serial production

- finally, both for H shaped aluminum extrusions and other products, we can bring you the profiles you asked us for wherever you are in the world in 2 working weeks only. This is thanks to our international supply service.

If you have any needs, our technical specialists are always available to provide you with the required support and help you solve any problems.

Tags:

Aluminum profileSep 29, 2022 12:00:00 AM