The special extrusions create parts made according to a specific design with high quality aluminum alloys, which often have highly complex technical characteristics. Since highly customizable, these special extrusions meet the most diverse needs of the various sectors: from furniture handles to glazing beads, from the corners of the vehicle steps to electromechanical components.

Profall special extrusions

Profall special extrusions include at least 12 different types:

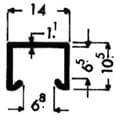

- special U profiles – for the electronic, electromechanical, automotive, domestic sectors and more;

- glazing bead profiles - to assemble doors and windows;

- borders with screw attachment - mainly used in shop and trade fair installations;

- vehicle borders - to finish commercial and industrial vehicles;

- joint covers with shank - conceived as finishing and joints for wood or other material panels;

- frames - for paintings, windows, doors, mirrors etc .;

- furniture handles - produced with infinite customizations in terms of shapes and sizes;

- drip trays and splash guards - for industrial vehicles;

- aluminum claws - for example, edging elements for furniture panels;

- special section corners - generally industrial vehicle step corners;

- handrails for stairs - widely used in the construction sector.

The strength of the special profiles made by Profall lies in the fact that, upon request, they can be totally customizable in shape and size. For example, the standard dimensional tolerances of some special profiles - such as U-profiles - are equal to +/- 0.15 mm, but in case of need, specific dimensional tolerances can be obtained, larger or smaller, upon customer request.

The strength of the special profiles made by Profall lies in the fact that, upon request, they can be totally customizable in shape and size. For example, the standard dimensional tolerances of some special profiles - such as U-profiles - are equal to +/- 0.15 mm, but in case of need, specific dimensional tolerances can be obtained, larger or smaller, upon customer request.

For this reason, a team of specialized technicians and engineers is always available to analyze requests quickly with prompt feasibility feedback.

Special extrusions: ask Profall

In the case of Profall, however, it is not just a matter of choosing the shapes and dimensions of the special extrusions, but of a real know-how that revolves around the production of aluminum profiles, and which is implemented year by year for guarantee a complete service that not all companies can guarantee.

New entry for Profall, for example, is the partnership with RCRAMERA for precise and detailed profile processing, including special extrusions. This includes a handful of services such as:

- aluminum cutting with various types of shearing machines to ensure even more precise reduced tolerances;

- aluminum blanking through technological software;

- aluminum surface finishes through brushing techniques, to remove impurities and allow hardness, shine and correct painting of special and standard profiles.

Special extrusions and beyond: Profall in Qatar

All this, as we have seen, is a guarantee of highly customized extrusions, but Profall goes further. In fact, we do not only make special profiles, but also semi-finished and whole products.

Read this very brief case history from 2019 to learn more.

After a thorough feasibility analysis, we managed to assure a well-known London-based architecture firm the production of a series of aluminum urban design furniture, specially designed for Doha.

In this case, these were bicycle racks for the bike paths in the capital of Qatar: the particular shape and the knurled surface to recall the tracks of the bike tires required a particular workload for Profall experts and engineers, but the result was excellent and is visible in Doha!

Tags:

Aluminum profileMay 11, 2020 12:00:00 AM