Let’s take a closer look:

- the difference between steel and aluminum in weight, corrosion resistance, cost, ease of manufacture and installation

- the advantages of Profall aluminum profiles

- all of our services, in addition to the manufacturing of profiles

The difference between steel and aluminum in 6 parameters

Weight

The first difference between steel and aluminum is in their weight. Aluminum profiles are lighter than steel profiles. This makes them more suitable for small structures, which are often provisional and positioned on intermediate floors. On the other hand, steel profiles are more suited to stable and durable structures, such as building systems made of concrete.

Corrosion resistance

Steel is more subject to corrosion than aluminum; therefore, aluminum profiles have more excellent corrosion resistance. However, if the steel profiles are made of stainless steel, a material that does not corrode and resists weather very well, the difference between aluminum and steel is more negligible, and the profiles have the same corrosion resistance.

Cost

Aluminum is more expensive than steel. For this reason, aluminum profiles are usually more expensive than steel ones. In any case, the cost of a profile depends not only on the raw material but also on the treatments and processing that the material must undergo; thus, the cost of aluminum and steel profiles varies according to the specific application needs.

Manufacturing ease

Another difference between steel and aluminum is manufacturing ease. Aluminum profiles are easier to make because aluminum is a much more malleable material than steel. As a result, processing costs are generally lower.

Installation ease

Aluminum extrusions are assembled through joints, while steel extrusions are usually welded together. Thus, aluminum profiles are easier to install and disassemble: that is why they are often used for temporary structures.

Can't choose between aluminum and steel?

Contact our team of experts: we will help you solve any doubts.

Why choose Profall aluminum extrusions

Besides the differences between steel and aluminum, there are also significant differences between the various aluminum profiles. Should I choose from standard or custom? It depends. At Profall, we carefully study your needs to make sure that the aluminum profiles fully meet your application needs.

We use 1050, 1070, 3003, 3103, 3004, 6060, 6063, 6005 aluminum alloys. As you can see, the range can cover all the technical needs of the reference sectors.

From our catalog, you can choose between aluminum profiles that are:

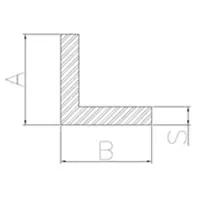

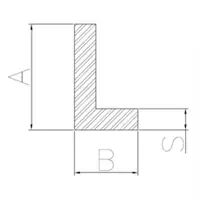

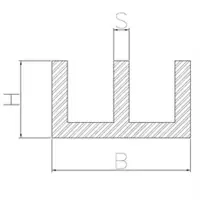

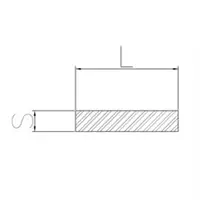

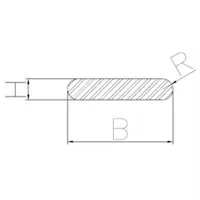

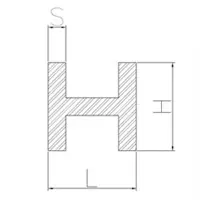

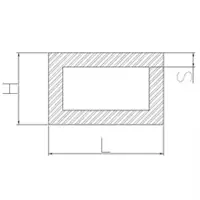

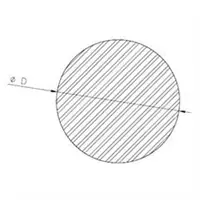

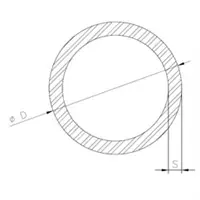

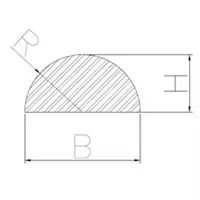

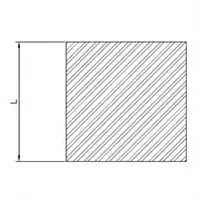

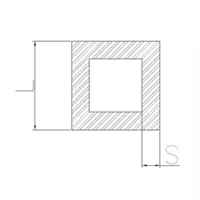

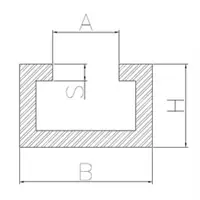

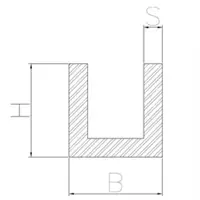

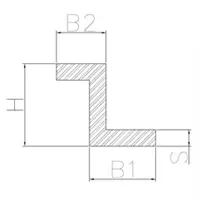

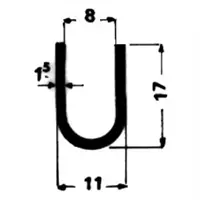

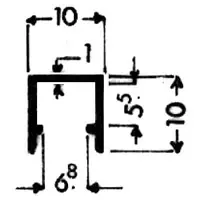

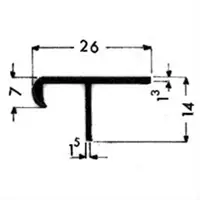

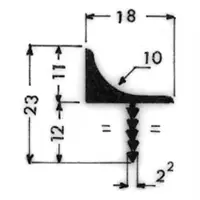

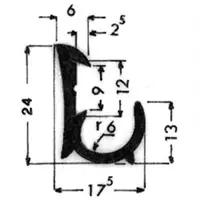

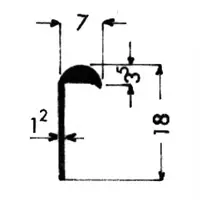

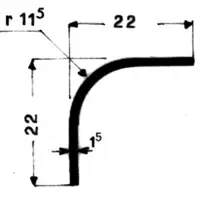

Standard. These are profiles with simple shapes, or those that are most commonly used in most production sectors: round or square bars, flat bars, round, square or flat tubes, simple U or double E channels, H, Z, and C profiles.

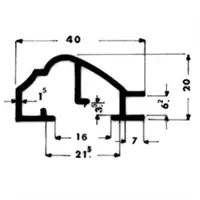

Special. All aluminum profiles are made to a specific design and with complex technical characteristics intended for various sectors. For example, these could be glazing bead profiles, automotive edges, joint covers, frames, handles, handrails, etc.

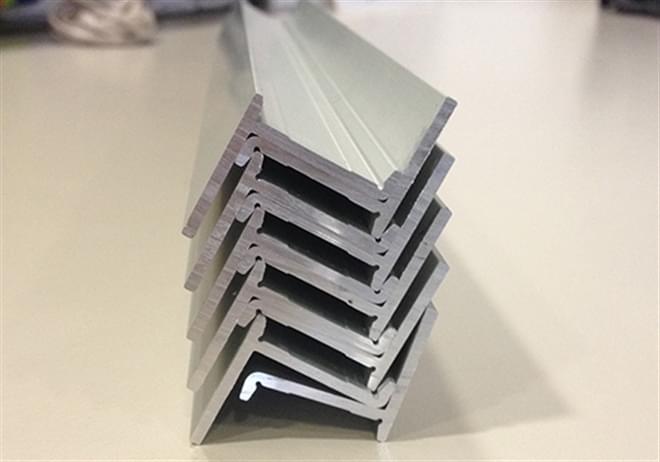

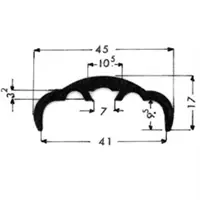

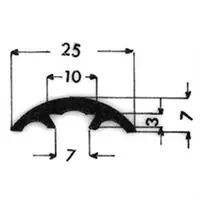

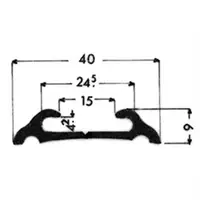

Aluminum borders with screw attachments

Aluminum borders with screw attachments

As an aluminum angle supplier, Profall can customize both types of profiles – depending on your specific needs. For example, we can make profiles with new shapes that have never been seen before, very thin profiles, or profiles with tolerances that the majority of suppliers cannot offer. The feather in our company’s hat is the manufacturing of custom aluminum profiles even with minimal dimensional tolerances and high technical complexity, which you will hardly find elsewhere.

Our services for aluminum profiles make the difference

Customization and the high technical complexity of production are not the only pluses of our company. The service quality is another central aspect that distinguishes the Profall brand.

When you choose our profiles, you will receive:

- a request analysis and feasibility feedback quickly

- quick prototyping and pre-serial production

- delivery of finished products in approximately two weeks

- after-sales technical support

The processing and post-production treatments that we can provide you

The experience of our engineers and specialized technicians, who are thoroughly familiar with the characteristics of aluminum, its advantages, and differences with steel, allows us to offer a high degree of customization and a very advanced level of detail. All your requests - profiles with extra-standard shapes, characteristics, tolerances - will be cared for by our designers.

Among the processing that we offer, you will find:

- aluminum cutting, with different types of saws and very tight tolerances

- shearing using cutting-edge software

- aluminum surface treatment, with advanced brushing techniques to remove any impurity and guarantee any color, hardness, and sheen

- aluminum packaging, with the possibility of applying logos, bar codes, and specific identifications according to the various needs.

Are you looking for a high-quality aluminum profile?

Tags:

Aluminum profileDec 14, 2017 12:00:00 AM