The extrusions manufactured by Profall are made with so-called soft alloys: these are essentially the alloys that belong to the 1000, 3000 and 6000 series.

In terms of aluminum content, alloys of the 1000 series have a minimum purity rating of 99.5%. This gives them a high capacity in terms of electrical and thermal conductivity. Furthermore, they are also extremely resistant to corrosion. They are typically utilized in the electrical and electromechanical industries.

Alloys of the 3000 series, which are mainly comprised of manganese, offer even greater resistance to corrosion, and are generally utilized for braze welding purposes. Products made using alloys of the 3000 series are typically utilised for heat exchangers and automotive applications.

Alloys of the 6000 series, on the other hand, contain Silicium and Magnesium. This family of soft alloys is characterized by its ease of processing and welding. In fact, these alloys are commonly used to manufacture welded structures and machined components. They are used to manufacture the majority of all specially-designed extrusions for industrial uses. This family includes one of the most used alloys in the extrusion industry: 6063 aluminum, widely employed to manufacture aluminum bars and tubing.

Profall utilizes a wide range of aluminum alloys: 1050 – 1070 – 3003 – 3103 – 3004 – 6060 – 6063 – 6005.

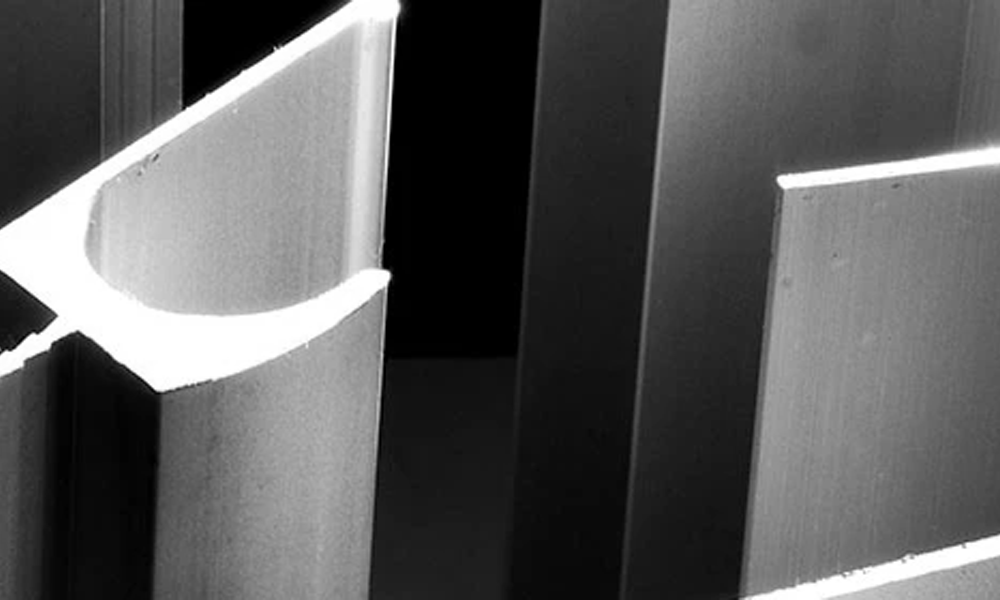

Aluminum profiles for every need, including those with hard-to-achieve technical characteristics.

With Profall, you have access to a world of unique possibilities, where every challenge finds its tailored solution.

Discover all the insights into our service for supplying standard profiles or custom extrusions based on customer designs and specifications.

Create without limits: get a quote for your custom aluminum profile.