The aluminum extrusions produced by Profilati Alluminio can be furnished with untreated surfaces, or else with various surface finishes. The latter can essentially be grouped into two main categories:

Aluminum extrusions with anodised surfaces are recommended whenever greater protection is required against potentially harmful external agents. Anodisation is a galvanic, or electrochemical, process that creates a layer of oxide on the surface of the extrusion. This layer serves to protect the metal against the harmful effects of the atmospheric agents, as well as to give it a certain colouration, which can either be neutral or else a variety of bronze shades, ranging from light (champagne) to dark.

Aluminum extrusions with coated surfaces, on the other hand, are recommended whenever certain aesthetic requirements need to be met. Coating is a process by which a layer of coloured material is deposited upon the surface of the extrusion. These normally consist of epoxy or electrostatic polyester powder coatings, which adhere well to the metallic surface and must be subjected to a secondary treatment in order to render the coating layer itself uniform.

Our coated extrusions in aluminum can be furnished in all the RAL colours, and can even be produced with special aesthetic effects, like the wood effect. These are particularly popular in the furnishing and technical furnishings industries.

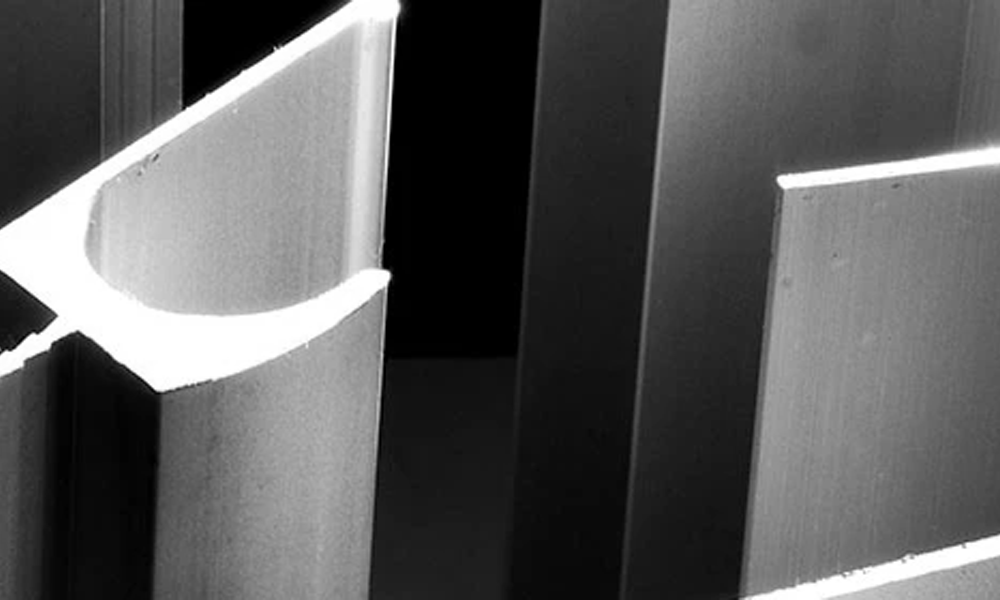

In the picture: examples of powder coated aluminum profiles

Furthermore, Profall is also capable of carrying out a wide range of mechanical processing operations upon its aluminum extrusions:

Aluminum profiles for every need, including those with hard-to-achieve technical characteristics.

With Profall, you have access to a world of unique possibilities, where every challenge finds its tailored solution.

Discover all the insights into our service for supplying standard profiles or custom extrusions based on customer designs and specifications.

Create without limits: get a quote for your custom aluminum profile.