Our aluminum extrusion profiles are produced through an extrusion process that, at certain temperatures, deforms the aluminum allowing the creation of a great variety of shapes and sizes, even the thinnest ones.

Complex shapes can be obtained through specific molds and thorough processes to gain high-quality, clean results. Let’s take a look at our range of aluminum extrusion profiles.

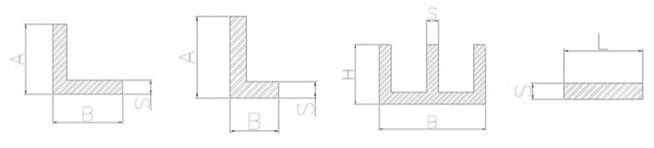

Our standard aluminum extrusion profiles include fifteen different, basic shapes that are required in many sectors: aluminum corner profiles, duct and double-duct profiles, flat round and square bars, square and round tubes and pipes; C profiles – also known as T-tracks – U channel profiles and Z profiles. Each aluminum extrusion profile is available in a wide range of different sizes and can be made with different aluminum alloys according to its destination.

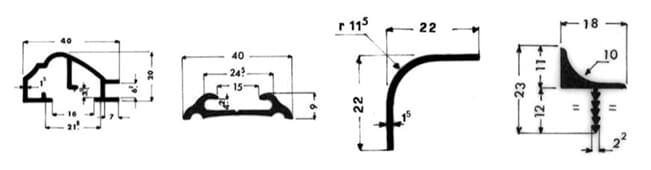

Our special aluminum profiles include complex shapes that are mostly used in the building-furniture sector, in the automotive sector and in the transport industry. Aluminum borders with screw attachments, drainers and water deflectors, glazing extrusions, picture frames, trim profiles for vehicles, corner elements with special sections, aluminum handles and handrails are just some of the special profiles we manufacture every day.

On request, a special design can be studied to meet specific requirements. Special aluminum extrusion profiles can be made with different aluminum alloys according to the aimed use.

For each commission we select the best way to obtain the desired output minimizing costs and production time, without sacrificing quality. Complex requirements are analyzed and translated into technical drawings that are shared with the customer. Once approved, the prototyping phase is aimed at testing the best way to produce the required product. Finally, the prototype is put into mass production.

Create without limits: get a quote for your custom aluminum profile.